Sheet metal fabrication is a pivotal process in the manufacturing industry, providing the framework for creating durable and precise metal components used across various sectors, including automotive, aerospace, and construction. Understanding its fundamental principles can open avenues for innovation and efficiency improvements within industrial applications. This article offers an in-depth exploration of sheet metal fabrication, from basic definitions to historical advancements, key processes involved, materials used, and vital safety considerations. Whether you're considering investing in precision sheet metal services or involved in metal fabrication design, this guide aims to equip you with the knowledge to appreciate the nuances of the field.

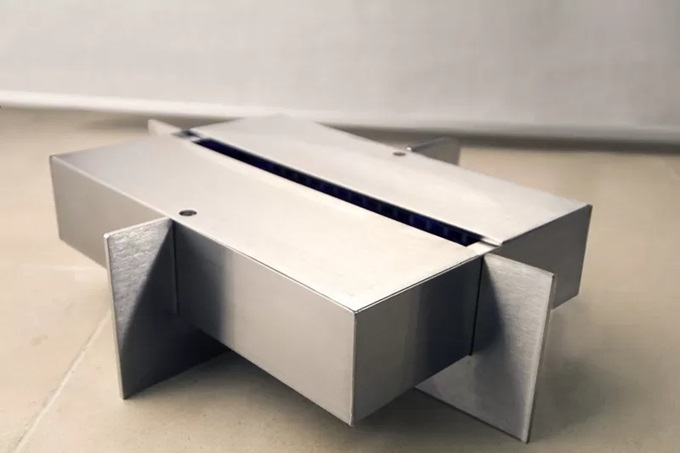

The term sheet metal fabrication refers to the process of transforming flat sheets of metal into specific shapes or structures through cutting, bending, and assembling. Essential in aerospace sheet metal fabrication, this technique involves several stages that require precision and skill. The finished products are crucial in creating everything from automotive panels to complex machinery components.

Fabrication typically starts with a thorough design phase where engineers utilize metal fabrication design software to plan out the specific parts needed. During this phase, factors like material properties and intended use come into play, guiding the subsequent steps of the process. Understanding the basic principles begins with familiarization with the key processes involved, such as cutting, bending, and assembly.

The sheet metal assembly process consists of several key stages, each requiring detailed attention to ensure the quality of the final product. Let's explore the primary processes involved:

Process | Description | Tools Used |

Cutting | Involves shearing, laser cutting, or punching to shape materials. | Shears, lasers, punch presses |

Bending | The process of deforming sheet metal along a straight axis to create bends. | Press brakes, tube benders |

Assembly | Combining multiple pieces to form a complete part or structure. | Welding machines, rivet guns |

Finishing | Surface treatments to improve sheets' appearance and durability. | Polishers, paint sprayers |

Each stage requires specialized tools and an understanding of both mechanical principles and the properties of materials being worked with. This expertise is why nuclear steel fabrication often demands stringent quality control and precision.

Materials used in sheet metal fabrication are chosen based on the intended application of the fabricated part and the required characteristics such as strength, flexibility, and resistance to environmental factors.

Material | Properties |

Steel | Durable, versatile, widely used in various sectors. |

Aluminum | Lightweight, corrosion-resistant, ideal for automotive and aerospace applications. |

Copper | Highly conductive, used in electrical applications. |

Brass | Corrosion-resistant, good for decorative parts. |

The choice of material directly influences the product's durability and suitability for its final application. For instance, aerospace sheet metal fabrication often prefers aluminum for its strength-to-weight ratio.

The development of sheet metal fabrication dates back several centuries, with origins in the early blacksmithing techniques used for creating tools and household items. As technology advanced, so did the complexity and precision of metalworking, leading to the sophisticated processes used today.

Significant historical evolutions in sheet metal work have come with the Industrial Revolution, which introduced machinery that could handle more metal with greater precision. More recent technological advances, such as computer-aided design (CAD) and computer numerical control (CNC) machining, have revolutionized metal fabrication design, allowing for high precision sheet metal creations that were previously unimaginable.

Maintaining safety in sheet metal fabrication is critical, given the machinery and materials involved. There are several standard practices and protective measures that should be adhered to in order to mitigate potential risks.

Operators need to wear appropriate protective clothing, such as gloves and safety goggles, to protect against cuts and eye injuries. Additionally, modern workshops are equipped with safety guards and emergency shut-off mechanisms to prevent accidents during operations. Regular training for workers on safe handling techniques is also crucial.

Moreover, ensuring that all equipment is regularly maintained can prevent malfunctions that could lead to workplace injuries. Organizations involved in bespoke metal fabrication must prioritize these safety measures to maintain a secure environment.

In conclusion, understanding the multifaceted nature of sheet metal fabrication from its fundamental processes to safety and historical evolution grants insight into the complexity and artistry involved in this field. Whether engaging with precision sheet metal for industrial applications or delving into aerospace sheet metal fabrication, knowledge of these key elements can greatly enhance your appreciation for this vital industrial process.

For customized sheet metal fabrication with flexible customization, high precision, and fast turnaround, choose SHARP CENTURY. With over 20 years of experience, advanced CNC and laser cutting technology, and top-tier welding certifications, we deliver reliable, durable components tailored to your exact specifications. Contact SHARP CENTURY today to optimize your manufacturing process with expert precision and efficiency.