The process of sheet metal fabrication forms the backbone of modern industrial production, especially in fields that rely on construction machinery, steel structures, and customized components. It involves transforming flat sheets of metal into finished products through a series of precise and controlled steps. A sheet metal fabrication company like sharp century, based in Taipei, ensures that every phase of the process aligns with strict quality standards to deliver parts that are both functional and durable. From the initial design to the final inspection, every stage contributes to achieving accuracy, efficiency, and performance.

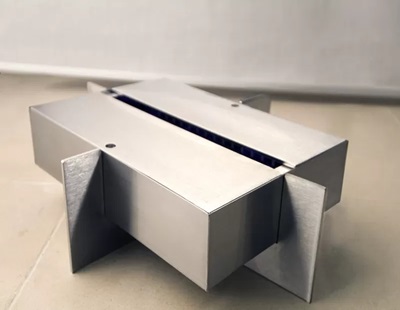

Every fabrication process begins with cutting and shaping the raw material. Advanced cutting technologies are used to ensure that the metal sheets are trimmed to the exact specifications of the design. Precision cutting not only reduces waste but also ensures consistent quality across large production runs. Shaping techniques such as bending or rolling follow the cutting stage, giving the metal its required form. A sheet metal fabrication company combines these processes seamlessly, ensuring that each piece is prepared for the more detailed stages of production. This step sets the foundation for the high accuracy demanded in industries such as construction and heavy machinery manufacturing.

After shaping, the next stage in sheet metal fabrication involves welding and assembly. Welding joins different components securely, ensuring that the final structure is strong and reliable. The assembly process may involve integrating multiple parts into a single unit, maintaining structural integrity and functionality. Surface treatment follows, providing protection against corrosion, enhancing the appearance, and ensuring that the product can withstand harsh working environments. Companies like sharp century place significant emphasis on these stages, as they determine not only the durability of the product but also its long-term performance.

Feature | Traditional Methods | Modern Sheet Metal Fabrication |

Precision | Dependent on manual skills | High accuracy through advanced machinery |

Efficiency | Slower and labor-intensive | Streamlined with automation and digital processes |

Material Utilization | Higher waste levels | Optimized for minimal waste and maximum efficiency |

Design Flexibility | Limited adaptability to complex projects | Capable of handling intricate, custom designs |

Product Consistency | Variable due to manual differences | Consistent results across large production volumes |

This comparison highlights how a modern sheet metal fabrication company ensures higher efficiency, precision, and reliability compared to traditional manual methods. Industries that rely on consistency and scalability benefit greatly from these advanced approaches.

The last stage of sheet metal fabrication is the inspection and delivery of the final product. Inspection ensures that every part meets the client's requirements and complies with industry standards. Quality checks focus on dimensions, surface finish, and structural integrity, making sure no detail is overlooked. Once approved, the fabricated parts are packaged and delivered for use in applications such as construction machinery or steel frameworks. A company like sharp century ensures that these processes are not only efficient but also tailored to customer needs, which is why they remain trusted in the field of industrial fabrication.