Aerospace engineering thrives on innovation and precision. Crucial aerospace sheet metal fabrication processes, a testament to the innovative spirit, constantly push the boundaries of aircraft and spacecraft development.

In this blog post, we will examine the vital role of sheet metal fabrication for aerospace applications and outline why it is necessary and a fundamental pillar of modern aviation and space exploration.

Precision aerospace sheet metal fabrication is crucial—it’s a cornerstone in the aerospace industry. Prototek manufactures parts that meet the strictest performance standards for aircraft and spacecraft. This level of precision is essential and a testament to the meticulousness and high standards required in this field.

Aerospace parts must be strong and lightweight. Precision sheet metal fabrication ensures that these parts can handle the stresses of flight while remaining reliable.

Reducing weight is vital for better fuel efficiency and increasing payload capacity. Precision fabrication allows manufacturers to build lighter parts without sacrificing strength or durability.

The design and finish of sheet metal parts affect how well an aircraft or spacecraft moves through the air. Accurate aerospace sheet metal forming techniques shape these parts correctly to improve airflow and reduce drag.

Safety is the top priority in aerospace. Precision sheet metal fabrication is a key element in our commitment to lower the risk of defects and inconsistencies, providing a reassuring level of safety and performance for essential components.

Aerospace often needs unique and complex parts. Precision fabrication techniques let manufacturers create these detailed components with high accuracy.

Aerospace parts must follow strict rules and certifications for safety and airworthiness. Precision sheet metal fabrication helps manufacturers produce parts that consistently meet these standards.

Here are six crucial sheet metal fabrication for aerospace in-house services at Prototek that can produce parts for the aerospace industry.

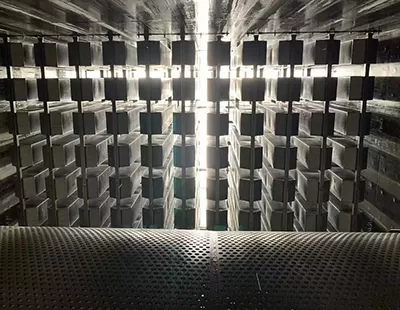

This method uses a focused laser beam to cut through sheet metal like aluminum, titanium, and stainless steel. Laser cutting provides precise and detailed cuts, making it perfect for parts such as brackets and support structures.

This technique uses a high-pressure stream of water mixed with abrasive materials to cut through thick sheet metal. Because it does not produce heat, it keeps the material intact. Waterjet cutting is excellent for making complex shapes and patterns needed in aerospace projects.

This technique uses a high-pressure stream of water mixed with abrasive materials to cut through thick sheet metal. Because it does not produce heat, it keeps the material intact. Waterjet cutting is excellent for making complex shapes and patterns needed in aerospace projects.

This type of EDM uses a specially shaped-electrode to create complex designs. Sinker EDM is suitable for making molds, dies, and detailed features in aerospace parts that need high accuracy.

Joining sheet metal parts uses different techniques, such as Metal Inert Gas (MIG), Tungsten Inert Gas (TIG), and spot welding. Welding is essential for building strong and reliable structures in aerospace applications.

This process combines several sheet metal components into a more significant part. Assembly methods include fasteners, bonding, and mechanical joining, which are critical for ensuring the strength and performance of aircraft and spacecraft.

These fabrication services help aerospace manufacturers produce various sheet metal parts, such as engine casings, control surfaces, mounting brackets, and structural elements, all crucial for safety and performance in the aerospace field.

The aerospace industry uses specific materials to make sheet metal parts. The most common materials include:

These materials are strong, lightweight, and rust-resistant. Popular types include 2024, 6061, and 7075.

These alloys are known for being strong, lightweight, and able to withstand high temperatures. A common type is Ti-6Al-4V, which is an essential material in parts for structures and engines.

This material is strong and resistant to rust and heat. Exhaust systems and engine parts use this material.

Inconel is a group of strong nickel-chromium alloys that resist corrosion and high temperatures. Jet engines and other high-heat parts typically use this material.

Carbon fiber-reinforced polymers (CFRP) and glass fiber-reinforced polymers (GFRP) are becoming popular because they are strong and lightweight, allowing for flexible designs.

Manufacturers may also use specialized alloys like beryllium copper, Hastelloy, and Monel to meet specific performance needs.

Choosing materials for aerospace sheet metal fabrication is essential. It requires balancing strength, weight, rust resistance, and ease of manufacturing. Precise fabrication methods help create reliable parts that can withstand the harsh conditions of flight and space travel.

Here are six key techniques for finishing and processing sheet metal in the aerospace industry. Each method helps improve how well aerospace parts work and how long they last:

This method gives a nice finish and protects parts from damage caused by the environment, such as rust and UV rays. Coatings can be adjusted for color, shine, and texture to meet branding needs and strengthen surfaces.

This eco-friendly method applies dry powder to parts and hardens them with heat, creating a durable finish. Powder coating sticks well to surfaces and resists chips, scratches, and fading. It is excellent for parts that face harsh conditions in aerospace.

Using a mesh stencil, designs, logos, or labels get printed directly onto sheet metal. It helps identify components and shows safety instructions or branding. Silk screening can create bright colors and fine details, essential for appearance and industry standards.

This process applies a protective coating to metal surfaces to prevent rust and oxidation. The coating creates a barrier that stops moisture and oxygen from reaching the metal, helping it last longer. It also makes the metal look polished and appealing.

These methods create a protective oxide layer on metal surfaces. Anodizing makes the surface harder and reduces rust while plating increases wear resistance and helps paint stick better. Both methods help aerospace parts last longer and ensure safety.

This process uses electricity to deposit a metal layer onto a part’s surface. It reduces friction and wear, especially in moving parts like gears and bearings. Electroplating also improves the conductivity and appearance of parts, making it useful in aerospace.

These techniques are essential for meeting the aerospace industry’s strict requirements for appearance and function, ensuring that parts can handle the harsh conditions they face during flights.

Quality assurance is crucial in aerospace sheet metal fabrication and manufacturing. Aerospace products are complex and play a vital role in safety. Maintaining high-quality standards is essential to ensure the reliability and safety of both aircraft and spacecraft.

Aerospace manufacturers follow essential rules to ensure the safety and soundness of their products. These rules cover materials, sizes, and performance.

Companies always look for ways to improve manufacturing. They try to fix problems and make their work faster.

Manufacturers check their products carefully during production. They look for mistakes to ensure everything is just right.

Manufacturers should check their suppliers to ensure they receive high-quality materials and parts.

Manufacturers must track their work. They write down every step they take so they can remember it and find any problems later.

By following these practices, aerospace manufacturers ensure their products are safe and ready to fly.

At Sharp Century, with over two decades of dedicated experience in sheet metal fabrication, we understand the unparalleled demands of the aerospace industry. Our journey has been defined by a relentless pursuit of precision, reliability, and innovation in every component we produce. We leverage advanced laser cutting machines and CNC machines, operated by a team of experienced manufacturing personnel whose skills are continuously enhanced through monthly training sessions.

Our commitment to excellence is reflected in our top-tier welding certifications, including EN-15085-CL1 and AWS, ensuring that every weld meets the most stringent aerospace standards. Furthermore, our ISO 9001 certified machining workshop guarantees rigorous quality control throughout the entire process, from concept to delivery. Whether you require cost-effective sheet metal prototyping solutions or high-volume production, Sharp Century offers cost-effective, on-demand aerospace sheet metal fabrication solutions with guaranteed on-time delivery. Our expertise in precision fabrication, honed in the demanding aerospace sector, also extends to other critical industries, including nuclear steel fabrication and mining fabrication, where robust, reliable components are paramount. We don't just manufacture parts; we build partnerships based on trust and a shared vision for aerospace advancement.

Ready to elevate your aerospace projects with unparalleled precision and quality? Contact Sharp Century today to discuss your specific aerospace sheet metal fabrication needs and learn how our expertise can contribute to your success.