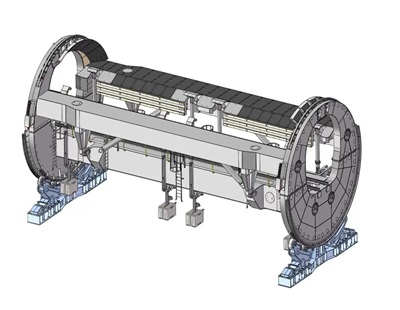

Manufacturing industries today demand accuracy, speed, and efficiency. With competition on a global scale, relying on standard machinery is often not enough to achieve the desired results. Industries such as construction, steel structures, and sheet metal processing require more advanced capabilities. This is where custom machinery solutions come into play, bridging the gap between standard equipment and industry-specific needs. By integrating advanced precision metal fabrication, companies like sharp century provide equipment that ensures consistent quality while meeting the rigorous demands of modern manufacturing.

Each industry faces its own production challenges, whether it is handling complex designs, maintaining tight tolerances, or working with difficult materials. Off-the-shelf machines may not be capable of addressing these issues effectively. Custom machinery solutions allow businesses to tailor equipment to their exact requirements. For example, a sheet metal processing line can be designed with precision cutting and shaping features that minimize waste and maximize efficiency. By combining innovative engineering with practical design, manufacturers achieve a balance between productivity and durability. The ability to design machinery around specific production goals ensures long-term operational efficiency and cost savings.

Feature | Standard Machinery | Custom Machinery Solutions |

Design Flexibility | Fixed and limited adaptability | Fully tailored to production requirements |

Accuracy and Precision | General tolerance suitable for basic tasks | High-precision capabilities for complex operations |

Cost Efficiency | Lower upfront cost but higher long-term use | Higher initial investment with reduced lifecycle cost |

Integration | Requires adjustments to existing processes | Designed to integrate seamlessly into workflows |

Innovation Support | Limited adaptability to new technologies | Supports automation, digital integration, and growth |

This comparison demonstrates that custom machinery solutions provide significant long-term benefits, particularly in industries where precision metal fabrication is crucial. While standard machines may be sufficient for basic operations, they often fall short when specialized processes or advanced designs are required.

The concept of precision metal fabrication is closely tied to the success of custom machinery. By designing equipment that incorporates cutting-edge fabrication technologies, manufacturers can ensure every component meets strict dimensional accuracy. This not only improves the quality of finished products but also reduces the need for rework and material waste. Precision-driven solutions are particularly valuable in sectors that rely on structural integrity, such as steel construction and heavy machinery. When integrated into custom machinery solutions, precision fabrication enables businesses to produce high-value components that meet both functional and aesthetic requirements.

In addition to improving current operations, custom machinery solutions help industries prepare for future challenges. Manufacturing trends increasingly emphasize automation, digital monitoring, and sustainability. Tailor-made machinery designed with these goals in mind allows companies to adopt new practices without overhauling their entire production system. As industries evolve, the integration of precision metal fabrication within customized designs ensures adaptability, resilience, and continuous innovation. Companies like sharp century highlight how forward-thinking solutions in machinery design can empower businesses to maintain efficiency and competitiveness in an ever-changing industrial landscape.