Bespoke metal fabrication is an essential part of many industries, offering tailored solutions that meet specific needs and requirements. This specialized form of precision sheet metal services involves the creation of unique, custom-designed metal parts and components that are not available off-the-shelf. By leveraging advanced metal fabrication design techniques and innovative sheet metal assembly processes, bespoke metal fabrication caters to a wide array of sectors, including automotive, aerospace sheet metal fabrication, construction, and more. This article explores the intricacies of bespoke metal fabrication, its customizable nature, the materials used, and its application across different industries. Whether you are involved in aerospace sheet metal fabrication or looking for unique solutions in bespoke metal projects, understanding this field can greatly enhance your projects and efficiency.

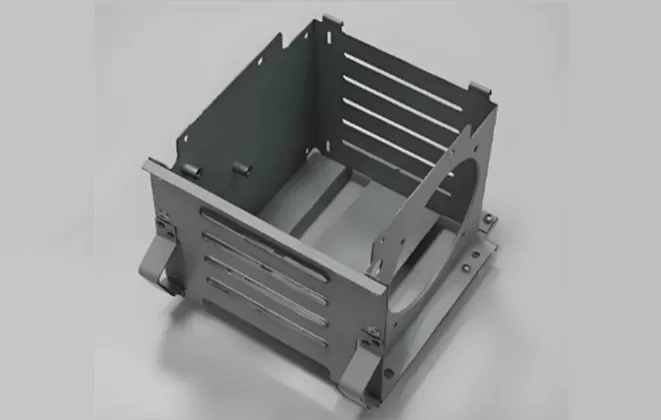

Bespoke fabrication, by definition, involves creating custom metal components tailored to specific client requirements. Unlike mass production, where items are manufactured to generic specifications, bespoke fabrication emphasizes uniqueness and specificity. This process often begins with a detailed consultation where the client's needs are thoroughly evaluated. The bespoke approach integrates precision sheet metal services with innovative metal fabrication design to produce components that precisely match the outlined specifications.

Bespoke fabrication is not limited to just creating parts; it also involves comprehensive services such as design consultation, prototyping, and testing. Each project is approached distinctively, ensuring that every element from form to function aligns perfectly with the customer's vision. This custom approach is what differentiates bespoke fabrication from standard metalwork, offering high levels of personalization and refinement.

The customization process in bespoke metal fabrication starts with a clear understanding of the client's requirements. This usually involves a series of planning sessions where project objectives, restrictions, and desired outcomes are defined. During these sessions, specialists in sheet metal assembly work closely with clients to develop technical drawings and prototypes.

Following the planning phase, materials are selected based on the specific needs of the project. Various factors such as durability, weight, and environmental conditions are considered to ensure optimal performance. Once materials are chosen, the fabrication phase begins, utilizing specialized techniques such as CNC machining, laser cutting, and welding to create precise metal components. The process is typically iterative, involving multiple rounds of prototyping and adjustments until the final product meets all specifications. Some projects may even require nuclear steel fabrication standards for enhanced durability.

Choosing the right materials is crucial in bespoke metal fabrication. The materials used not only affect the appearance and feel of the final product but also its performance and longevity. Common materials include:

Material | Properties | Application |

Stainless Steel | Corrosion resistant, high strength | Kitchen appliances, construction |

Aluminum | Lightweight, malleable | Aerospace, automotive |

Titanium | Strong, resistant to extreme temperatures | Aerospace, medical devices |

Copper | Electrical conductivity, ductility | Electrical components, plumbing |

Each material is chosen based on the specific demands of aerospace sheet metal fabrication, automotive requirements, or more generic applications in construction and industrial sectors. The versatility of materials allows bespoke projects to be both innovative and functional.

Bespoke metal fabrication is widely used across numerous industries due to its ability to deliver unique and highly specialized components. Industries such as aerospace demand components that adhere to strict regulations and performance criteria, making bespoke fabrication a perfect fit.

In the construction sector, bespoke services provide architectural elements like custom facades and durable interior design components. The automotive industry also benefits immensely from bespoke solutions, particularly in racing car components where precision is crucial. Additionally, bespoke fabrication finds valuable applications in the creation of intricate medical equipment, where custom specifications are often essential for functional and safe medical devices.

Several compelling case studies highlight the effectiveness and versatility of bespoke metal fabrication. One notable example is a project involving the creation of custom heat-resistant exhaust systems for high-performance vehicles, where bespoke metal fabrication ensured optimal performance and efficiency.

Another example comes from the field of aerospace sheet metal fabrication, where bespoke services were employed to develop lightweight yet durable structural components for a new line of environmentally friendly aircraft. The project required a combination of precision sheet metal services and advanced materials to achieve the fuel efficiency goals set by the airline.

In the architectural sector, bespoke metal fabrication enabled the transformation of a veritable historic building facade, providing both aesthetic appeal and increased durability using tailored stainless steel components. These case studies underscore the transformative potential of bespoke fabrication across various sectors.

Bespoke metal fabrication stands at the intersection of art and engineering, offering unparalleled opportunities for customization and precision in metalwork. As explored in this article, understanding bespoke fabrication processes, material selection, and industry applications can significantly augment the capabilities of projects across a spectrum of fields. Whether you are involved in creating unique construction elements or high-performance vehicle components, embracing the ethos of bespoke fabrication ensures that your project benefits from heightened quality, specificity, and innovation. For tailored solutions with flexible customization, high precision, and fast turnaround, contact SHARP CENTURY today to elevate your bespoke metal fabrication projects with unmatched quality and reliability.