In modern manufacturing, sheet metal parts are widely used in fields such as electronic devices, automobiles, rail transit, aerospace, and industrial machinery due to their lightweight, high strength, and formability. Sheet metal components are not only key structural parts of products but also directly impact the performance and durability of the final equipment. The bespoke metal fabrication and custom processing services provided by Sharp Century transform customers' design concepts into high-precision, functionally reliable real parts through precision metal design and efficient production processes, laying a solid foundation for high-performance equipment across various industries.

In the field of sheet metal component processing, Sharp Century is renowned for its customized and integrated services. The company utilizes advanced CAD/CAM systems for sheet metal fabrication design, optimizing flat layouts and bending factors, and conducts Design for Manufacturability (DFM) analysis to ensure high precision and feasibility during processing and assembly. Through complete processes such as precision cutting, bending, stamping, welding, and surface treatment, Sharp Century can provide small-batch prototypes or large-scale production according to customers' personalized needs, ensuring that each sheet metal component meets the stringent standards of modern manufacturing in terms of structural strength, dimensional accuracy, and surface quality—thereby enhancing the overall performance of the product.

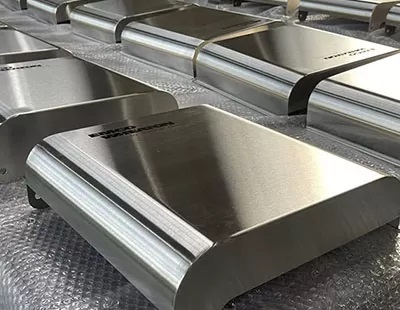

In modern industrial equipment, the materials and processing techniques of sheet metal parts directly affect the stability, service life, and safety of the equipment. For example, stainless steel components are suitable for high-humidity and highly corrosive environments, while aluminum alloys can maintain strength under lightweight requirements. Sharp Century ensures that parts operate stably under high loads and complex conditions—meeting the rigorous quality levels required in nuclear steel fabrication and aerospace sheet metal fabrication —by combining metal design with precise sheet metal fabrication technologies, while also improving the overall reliability and production efficiency of equipment. Custom processing services can optimize design and material selection based on customers' actual needs, allowing each sheet metal component to perform at its best.

In sheet metal fabrication, different materials and processing techniques directly affect the durability, functionality, and production efficiency of parts. The table below compares commonly used materials and their applicable processing methods:

Material Type | Main Properties | Applicable Processing Techniques | Typical Applications |

Carbon Steel | High strength, good weldability | Cutting, bending, welding | Chassis, brackets |

Stainless Steel | Corrosion-resistant, high temperature resistant | Cutting, stamping, bending | Industrial equipment enclosures, kitchen equipment |

Aluminum Alloy | Lightweight, good thermal conductivity | Bending, stamping, welding | Aerospace components, electronic housings |

Copper & Copper Alloys | Excellent electrical conductivity | Cutting, bending | Electrical connectors, conductive plates |

As shown in the table, Sharp Century can select the most suitable materials and processing techniques for different application scenarios in sheet metal manufacturing, optimizing part performance while balancing production efficiency and structural stability—offering customers high value-added custom solutions.

With the development of intelligent manufacturing and industrial automation, sheet metal processing is gradually moving toward high precision, digitalization, and multi-functionality. In the future, more high-performance composite materials and automated processing technologies will be applied to sheet metal component production to achieve comprehensive improvements in lightweight design, wear resistance, precision, and production efficiency. Sharp Century, by integrating sheet metal fabrication, metal fabrication design, and custom processing services, will continue to provide high-quality sheet metal parts that meet the needs of future industrial development, helping enterprises maintain a competitive edge in modern manufacturing.