Services

Design Optimization

Sharp Century utilizes lightweight materials such as high-strength alloy steels and composite materials to reduce equipment weight and lower energy consumption.

Strengthening of Critical Components

Applying heat treatment processes to load-bearing components to enhance their wear resistance and fatigue strength.

Efficiency Improvement

Deploying welding robots and CNC machining centers to increase traditional processing efficiency by over 30%.

Standardization

Establishing detailed assembly and inspection procedures to minimize human errors.

Sheet Metal Processing

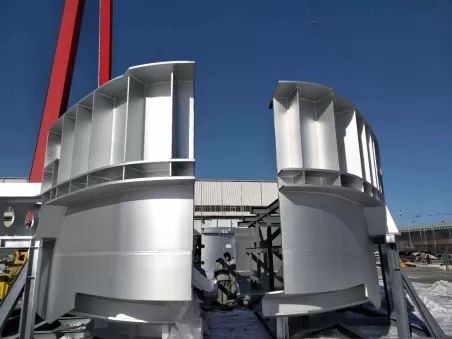

The process includes material cutting → forming → joining → surface treatment → assembly and final assembly. We are ready to offer premium services in sheet metal fabrication and assembly.

Services

The manufacturing of mining machinery is a complex process that encompasses design, material processing, assembly, and testing. Below is a comprehensive introduction to the entire manufacturing process, integrating key technologies such as sheet metal processing, welding, and machining:

1. Requirement Analysis and Design Phase

2. Raw Material Preparation and Pre-treatment

3. Core Manufacturing Process

Sheet Metal Manufacturing: Material cutting → Forming → Joining

Heavy Structural Welding: Welding process selection (welding method); Quality control (pre-welding and post-welding preparations).

Machining: Machine tool processing (turning and milling); Special processes (heat treatment and surface hardening).

Assembly and Final Assembly: Sub-assembly; Final assembly and debugging.

Surface Treatment and Coating

Quality Inspection and Testing

Sharp Century offers robust sheet metal fabrication capabilities to produce components that meet strict quality and performance standards.

Services

Common Issues and Solutions in Mining Equipment Fabrication:

Excessive burrs on material cutting edges

Optimize cutting parameters (reduce laser power, increase cutting speed).

Cracking or excessive springback after sheet metal bending

Adjust the bending radius (typically ≥1.5 times the sheet thickness); Orient the bending direction perpendicular to the material grain direction (avoid bending along the rolling direction); Implement bending compensation.

Welding distortion causing assembly misalignment

Use segmented welding to reduce localized heat accumulation; Employ welding fixtures to secure the workpiece; Perform mechanical straightening after welding.

Coating peeling or bubbling after painting

Perform sandblasting before painting; Control the painting environment; Use epoxy zinc-rich primer to enhance adhesion.

Excessive flatness deviation in large sheet metal components

Apply vibration stress relief after welding to eliminate residual stresses; Store large flat components vertically to prevent deformation due to self-weight.