Services

Services

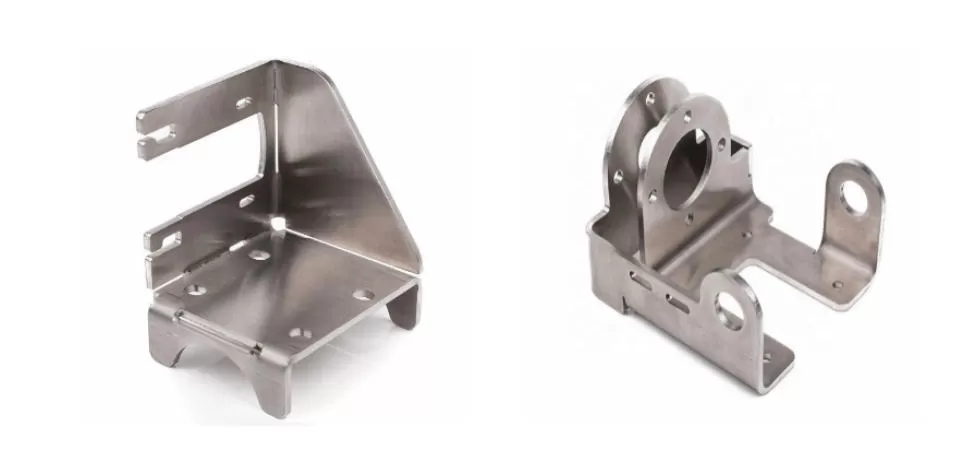

Flexible Customization

Whether you need simple brackets or complex enclosures, Sharp Century tailor our fabrication process to your exact design requirements. We work closely with you from prototype to production, offering custom sizes, materials, finishes, and assembly options to perfectly fit your project needs.

High Precision and Quality

We utilize state-of-the-art laser cutting, CNC bending, and welding equipment to produce sheet metal parts with tight tolerances. Our skilled technicians ensure each piece meets strict quality standards, resulting in reliable and durable components that perform well in demanding applications.

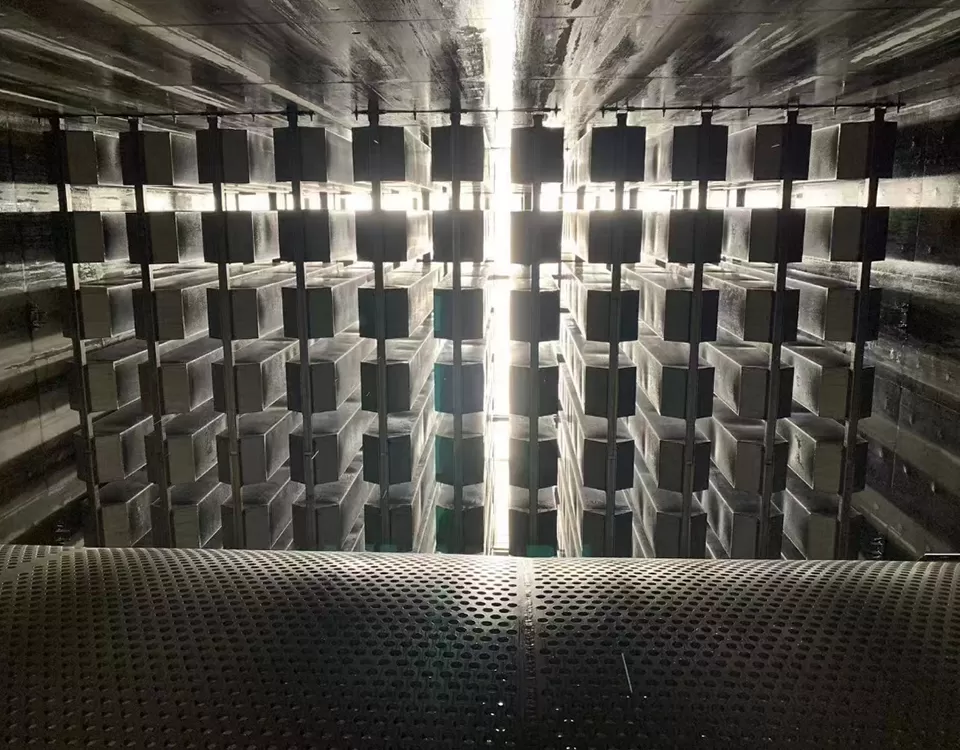

Fast Turnaround Time

Our streamlined workflow and custom machinery solutions allow us to complete orders efficiently while maintaining high quality. We understand the importance of timely delivery in your supply chain and strive to meet or exceed deadlines, helping you keep your projects on schedule.

Services

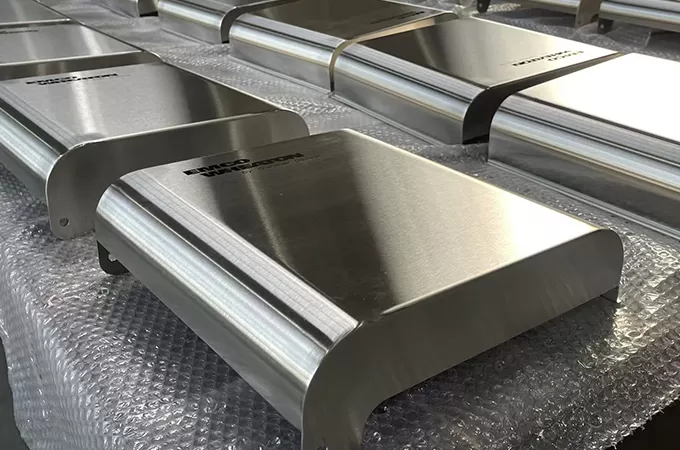

There is no clear semantic distinction between the processing industry and the manufacturing industry. Both involve using certain means of production to manufacture products from objects of labor, and both fall within the industrial sector.

In everyday economic activities, the processing industry typically refers to the activity of processing raw materials provided (or specified) by a client according to the client’s technological requirements. The production process and the resulting products belong to the client, and the processor’s remuneration comes from the processing fees paid by the client.

In contrast, the manufacturing industry usually refers to the activity of independently purchasing raw materials and organizing production according to one’s own technological processes. The products belong to the manufacturer, and the manufacturer’s remuneration is derived from the profit margin generated in the entire process from raw materials to finished products.

Services

Sheet metal manufacturing is achieving breakthroughs through innovative industrial technologies. Automation and intelligence are the core trends, with advanced equipment such as laser cutting, CNC bending, and welding significantly enhancing precision and efficiency. The application of IoT technology has enabled equipment connectivity and real-time monitoring, optimizing the production process.